Rotary Drilling: A Complete Guide to History, Innovations, and Applications in Modern Resource Extraction

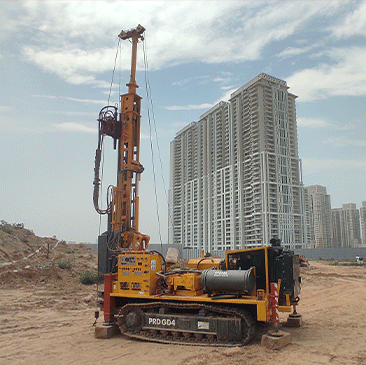

Discover how rotary drilling has evolved from its origins to today’s advanced systems, and see why the PRD-BH-30-160 stands out as a powerful, reliable choice for modern drilling projects.